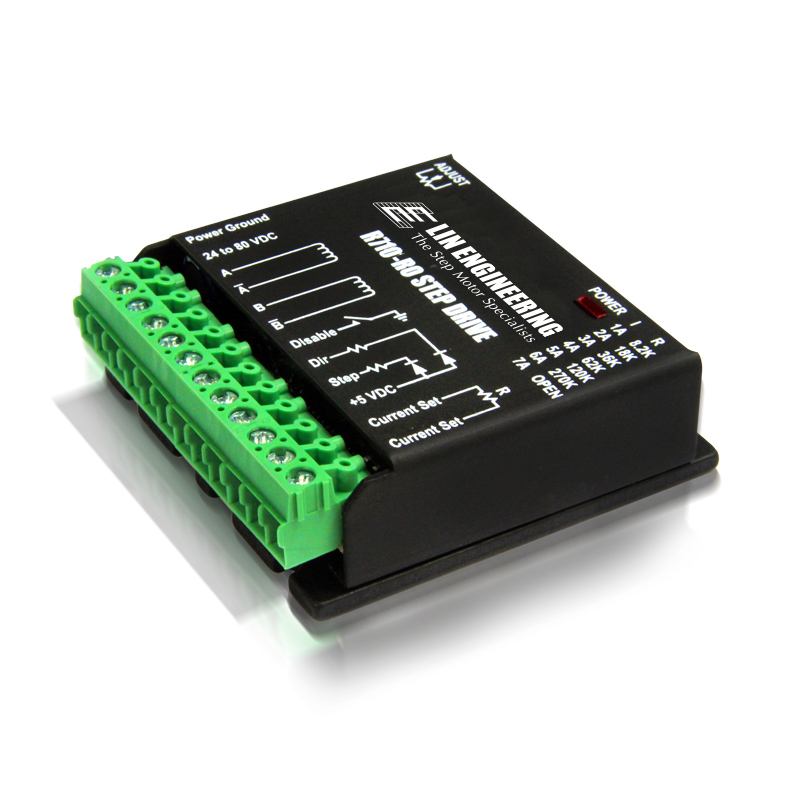

R710

MICROSTEPPING DRIVER

- Built-in step pulse multiplier 1, 2, 5, and 10

- Common Ground or Common +5 Volts Input Option Available

- 10 microstepping driver • Optically isolated Step, Direction, and Disable/Enable inputs

- Automatic Current Reduction

- Adjustable trimpot for noise and vibration reduction

- Operates from 24 to 80 VDC

- Selectable Driver Peak Current Ranges: 1 to 7 Amps OR 0.3 to 2 Amps

- Low Power Dissipation from 1 to 12 Watts (1 to 7 Amps)

- Excellent sinusoidal current waveform for smooth operation

- Low current ripple for low noise

- Low Cost

- High Efficiency

Part Number:

R710-RO

Unit Price:

$198.00 USD

Ships Within:

5 Business Days

Estimated Inventory:

5 Units

The potentiometer shown on the board can be rotated using a screwdriver. It’s recommended to rotate the motor at 0.25 RPS. Then to adjust the potentiometer until there is the least amount of vibration and noise coming out of the motor. This will be the position that the driver will perform smoothly with a given motor and power supply voltage.

The adjustment will alter the current waveform coming out of the driver and into the motor coils.

R710 -INCLUDES A BUILT-IN STEP PULSE MULTIPLIER BOARD

The R710 has the same features as the R701 plus two additional features:

Input Option Header – allows the use of a Common Ground or a Common +5VDC for optically isolated inputs

Input Option Header – allows the use of a Common Ground or a Common +5VDC for optically isolated inputs

Step Pulse Multiplier – will always output 10 microstepping, even with a step input of Full Step, Half Step, 5 Microstep, or 10 Microstep. The user no longer needs to change their original setup to get microstepping. Simply select the desired step multiplier of 1, 2, 5 or 10; to achieve the 10 microstepping output from the driver, while maintaining the rotational speed that you had in your original setup.

| PIN NUMBER | FUNCTION |

|---|---|

| 1 | Power Ground |

| 2 | +24 to 80 VDC |

| 3 | A Phase |

| 4 | A Bar Phase |

| 5 | B Phase |

| 6 | B Bar Phase |

| 7 | Disable |

| 8 | Direction |

| 9 | Step |

| 10 | +5 VDC |

| 11 | Current Set |

| 12 | Current Set |

To set the Current with the Correct Resistor, use the following Table:

| CURRENT (Amps) | RESISTANCE (Ohms) |

|---|---|

| 1 | 8.2K |

| 2 | 18K |

| 3 | 36K |

| 4 | 62K |

| 5 | 120K |

| 6 | 270K |

| 7 | OPEN |

- INPUT VOLTAGE: +24 to 80

- DRIVE CURRENT(PER PHASE): 0.3 to 2 Amps or 1 to 7 Amps

- ISOLATED INPUTS: Step Clock, Direction, Enable & Disable

- STEP FREQUENCY (MAX): 200kHz

- STEPS PER REVOLUTION (1.8º MOTOR): 2000

Drivers & Controllers

-

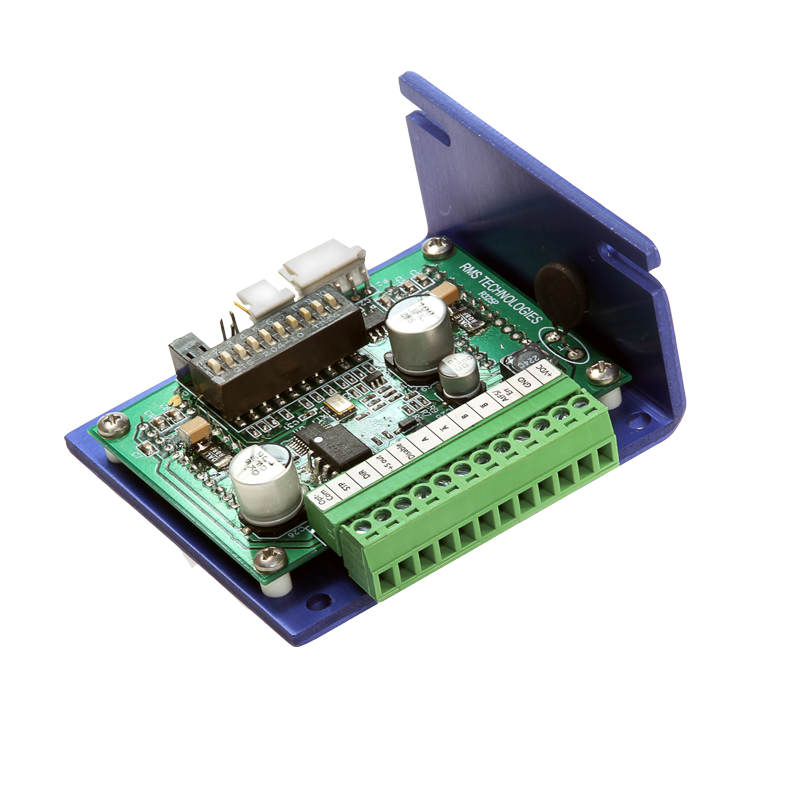

R208 MICROSTEPPING DRIVER

Features & Benefits

Features & Benefits- Bipolar Step Motor Driver

- Operates from +12 to 24 VDC

- Phase current ranges from 0.35 to 2.0 Amps Peak

-

R325P SINGLE AXIS DRIVER

Features & Benefits

Features & Benefits- Operates from +12 to 48 VDC

- Phase current from 0.3 to 3.0 Amps Peak

- Step Resolutions from Full to 256 microstepping

Stepper Motors

-

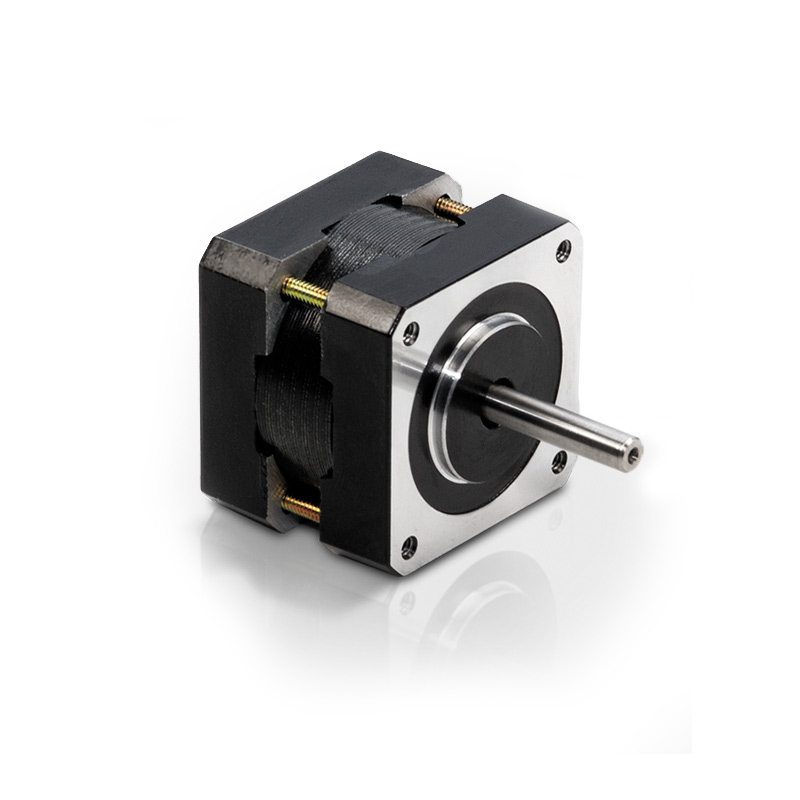

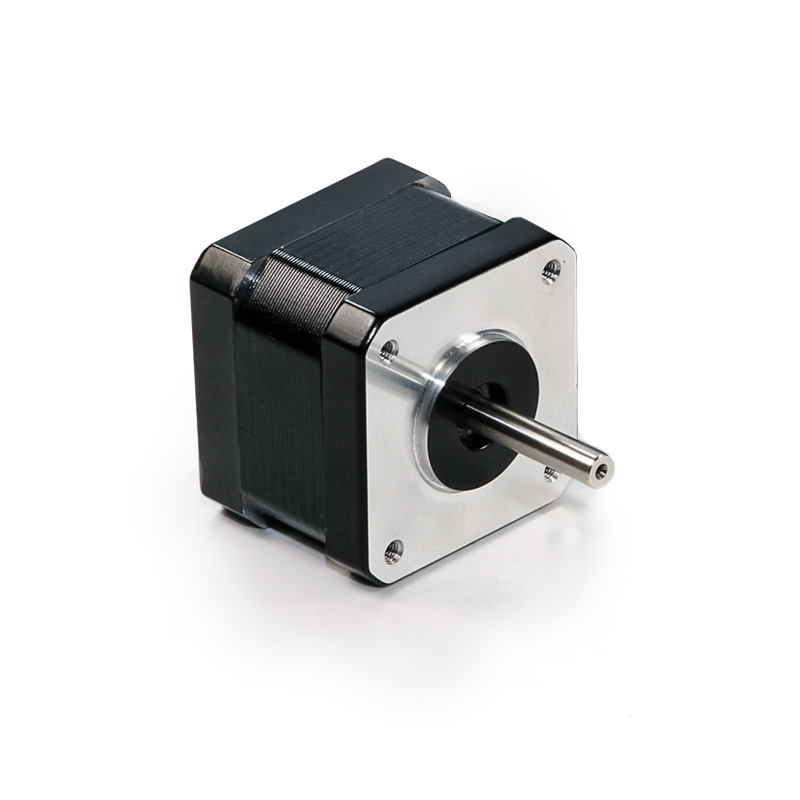

208 Series Compact Stepper Motor

Features & Benefits

Features & Benefits- Small, Compact Size

- Cost Effective

- Up to 4 oz-in (0.03 N-m) Holding Torque

-

211 Series Compact Stepper Motor

Features & Benefits

Features & Benefits- Small, Compact Design

- Cost Effective

- Up to 16.6 oz-in (0.12 N-m) Holding Torque

-

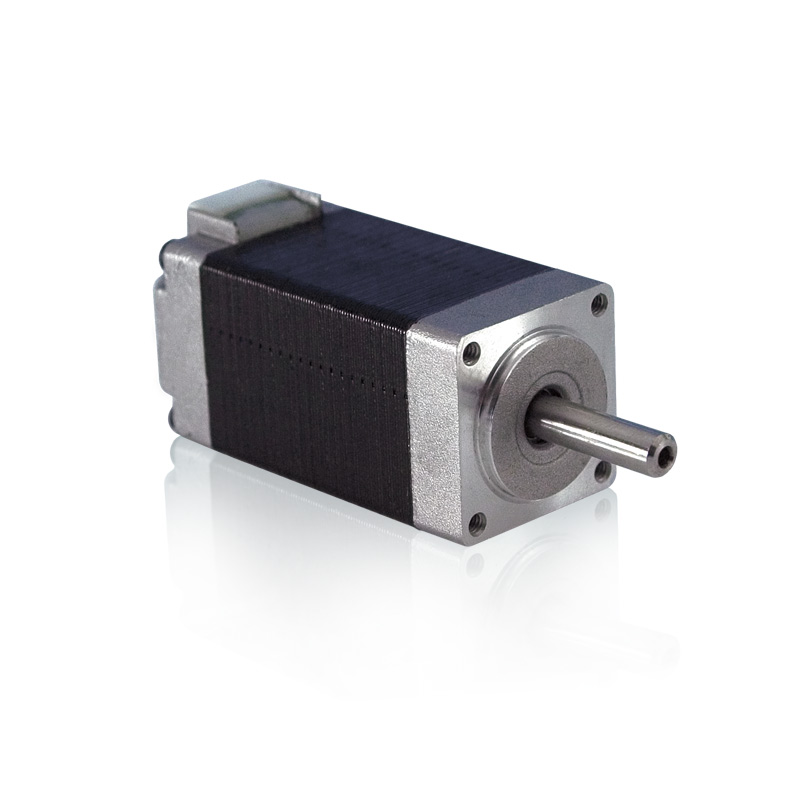

3518 Series High Torque Stepper Motor

Features & Benefits

Features & Benefits- Ideal for limited mounting space

- Cost Effective

- Up to 20 oz-in (0.14 N-m) Holding Torque

-

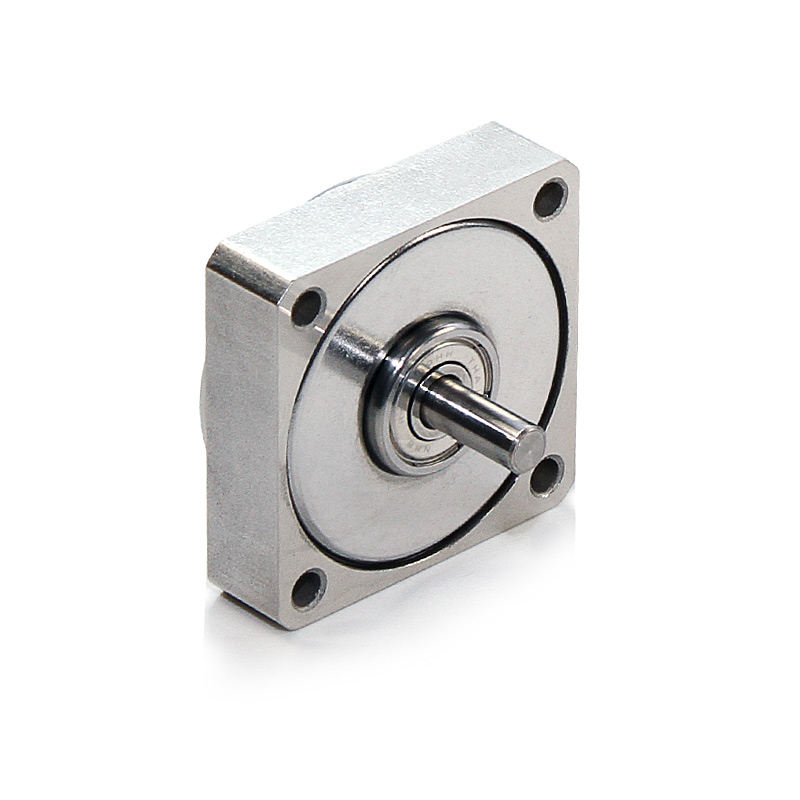

3709 Series Xtreme Accuracy Stepper Motor

Features & Benefits

Features & Benefits- Signature Series Technology for ultimate smooth motion and high accuracy

- 7 different mounting options

- Up to 22 oz-in (0.15 N-m) Holding Torque

-

3809 Series Xtreme Accuracy Stepper Motor

Features & Benefits

Features & Benefits- Signature Series Technology for ultimate smooth motion and high accuracy

- Ideal for custom housings

- Up to 16 oz-in (0.12 N-m) Holding Torque

-

4018 Series

Features & Benefits

Features & Benefits- Slim, Compact Design

- Cost Effective

- Up to 42 oz-in (0.30 N-m) Holding Torque

-

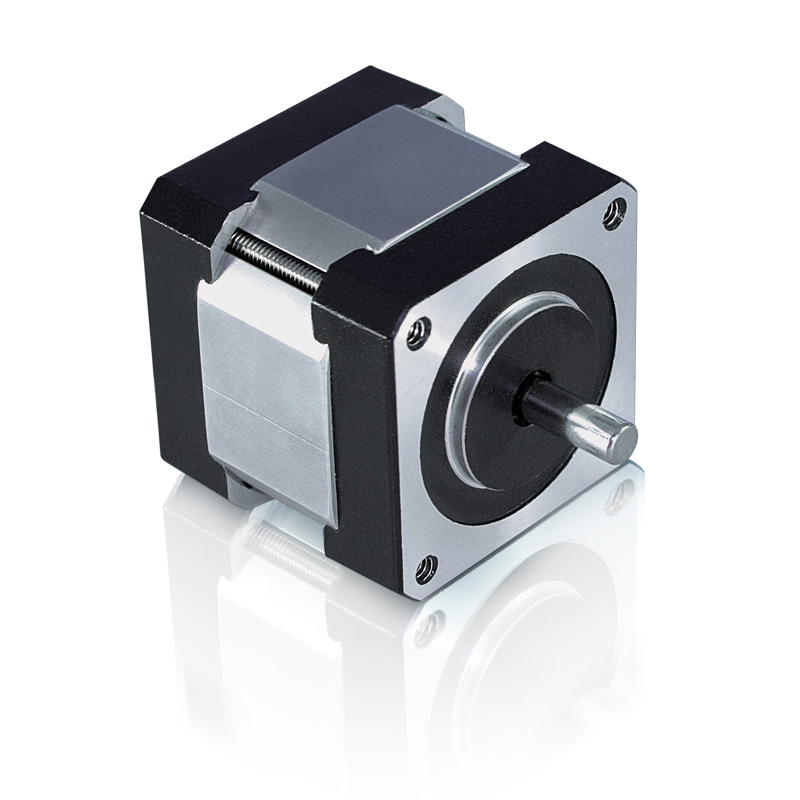

4118 Series High Torque Stepper Motor

Features & Benefits

Features & Benefits- More torque than standard NEMA 17 stepper motors

- Custom wound for high speed or low speed applications

- Up to 115 oz-in (0.81 N-m) Holding Torque

-

416 Series Xtreme Accuracy Stepper Motor

Features & Benefits

Features & Benefits- Signature Series Technology for ultimate smooth motion and high accuracy

- Patented design

- Up to 8.4 oz-in (0.06 N-m) Holding Torque

-

417 Series Xtreme Accuracy Stepper Motor

Features & Benefits

Features & Benefits- Signature Series Technology for ultimate smooth motion and high accuracy

- Patented design

- Up to 30 oz-in (0.21 N-m) Holding Torque

-

4209 Series High Accuracy Stepper Motor

Features & Benefits

Features & Benefits- Smooth motion and high accuracy

- Patented design

- Up to 62 oz-in (0.44 N-m) Holding Torque

-

4418 Series Xtreme Torque Stepper Motor

Features & Benefits

Features & Benefits- Up to 35% more torque than standard NEMA 17 stepper motors

- Custom wound for high speed or low speed applications

- Up to 100 oz-in (0.71 N-m) Holding Torque